Intelligent Power Monitoring: Smart Power Monitoring System Solution

1.System Overview

Core Positioning: AI-Driven Adaptive Power Security Guardian

The Intelligent Power Monitoring system is a new-generation power monitoring solution designed for the future. It breaks through the limitations of "passive alarm" inherent in traditional monitoring systems. By integrating edge computing, cloud computing, and artificial intelligence technologies, it constructs an integrated active defense system encompassing "perception - analysis - decision - early warning." The core value of the system lies in its adaptive learning and proactive warning capabilities. It not only monitors the operational status of the power system in real-time but also gains deep insights into potential risks, accurately locates faults, and provides scientific handling suggestions. Ultimately, it serves as an intelligent security guardian, ensuring the safe, stable, and efficient operation of critical power facilities.

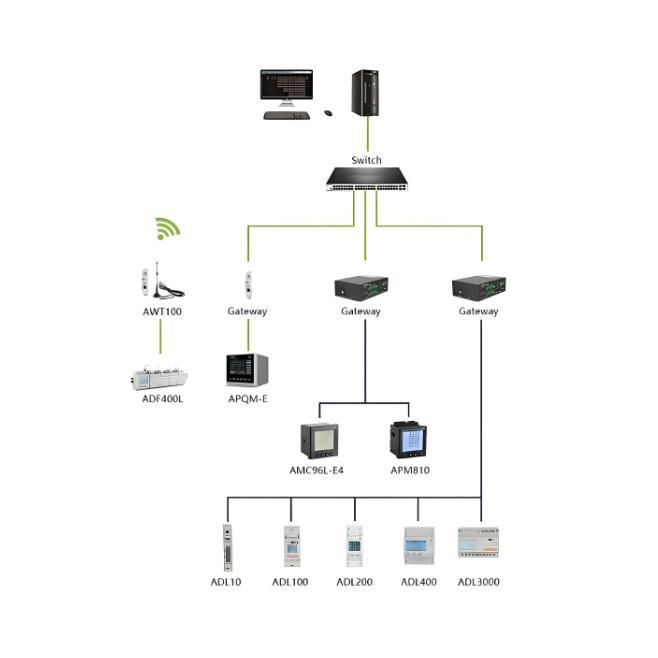

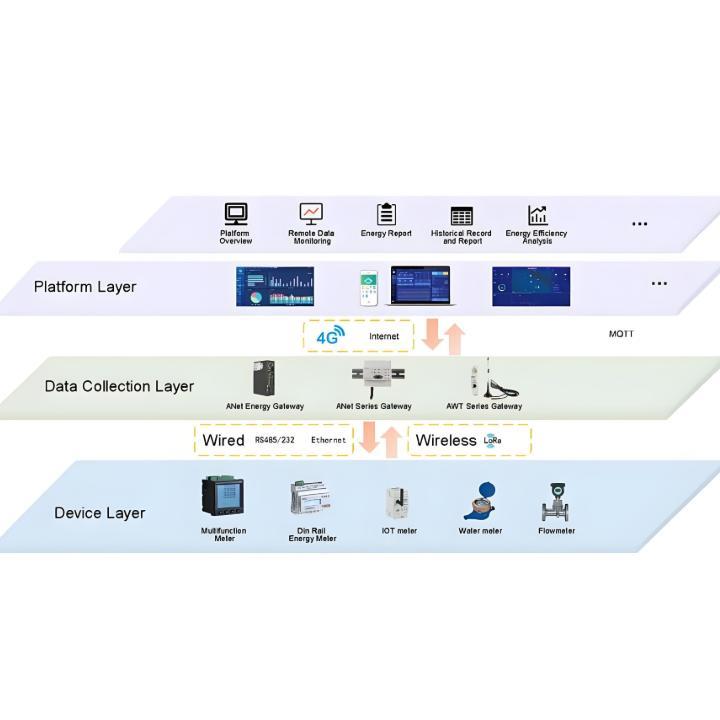

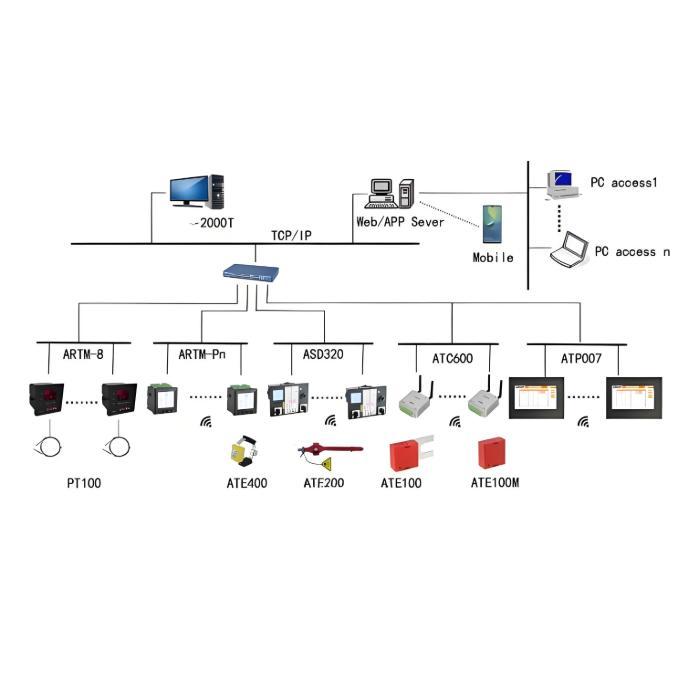

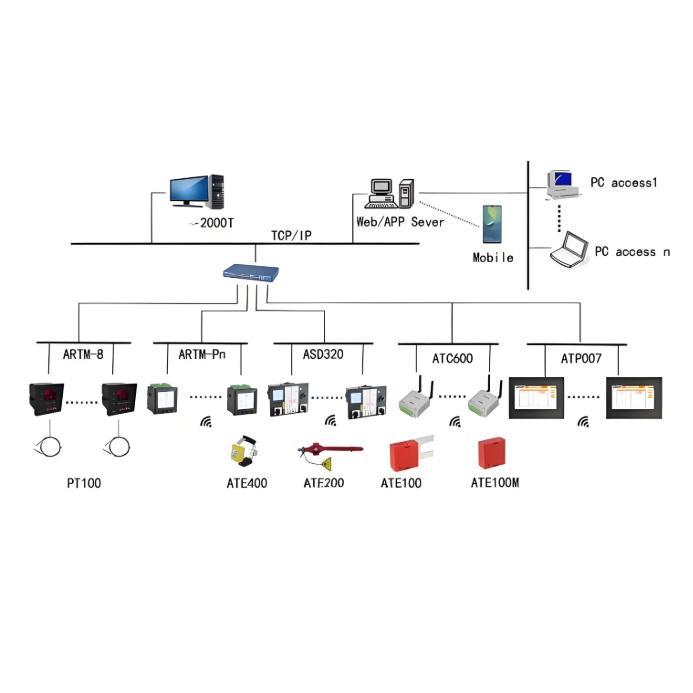

2. Technical Architecture

This system adopts an advanced "Cloud-Edge" collaborative architecture, balancing real-time performance, intelligence, and evolvability.

- Edge Side:

- Deployment: Deploys intelligent acquisition terminals integrated with AI chips on-site, such as in substations and distribution rooms.

- Function: Enables localized real-time data processing and anomaly detection. Provides rapid response and preliminary judgment for microsecond to millisecond-level fault characteristics like arc flashes and transient disturbances, ensuring extremely low latency for critical alarms. The edge side possesses a certain degree of autonomous decision-making capability, allowing it to execute core protection logic even when cloud connectivity is interrupted.

- Cloud Side:

- Deployment: Built on a highly available cloud platform, responsible for the storage and mining of massive historical data.

- Function: The cloud serves as the system's "wisdom brain," training fault prediction models and equipment health assessment models through machine learning algorithms. The models support online iterative updates, enabling continuous self-optimization as operational data accumulates, leading to sustained improvement in prediction accuracy. Simultaneously, the cloud provides a unified operation and management portal.

- Collaboration Mechanism: The edge side is responsible for "immediate reaction," while the cloud side handles "long-term learning." Optimized models trained in the cloud are periodically or on-demand pushed down to the edge side, enabling the continuous evolution of the entire system's intelligence level.

3. Typical Functions

3.1 Arc Fault Location and Protection

- Technical Principle: Captures specific electromagnetic radiation characteristics generated by fault arcs through high-frequency sampling technology. The edge AI chip analyzes the electromagnetic waveform in real-time and, combined with multi-probe information, utilizes algorithms for topological localization.

- Core Value: Can accurately locate the fault point within switchgear or cable lines within milliseconds, and quickly trip the faulty circuit. This significantly contains the fault scope, prevents accident escalation, and protects personnel and equipment safety.

3.2 Comprehensive Equipment Health Assessment and Predictive Maintenance

- Monitored Parameters: Comprehensively monitors multi-dimensional status parameters of critical power equipment (e.g., transformers, switchgear, cable terminations), such as vibration, temperature, and partial discharge.

- Core Functions:

- Health Score: Generates a dynamic health score for each piece of equipment based on AI model analysis of multi-source data fusion.

- Automated FMEA Report Generation: The system can automatically generate Failure Mode and Effects Analysis reports compliant with industrial standards, clearly presenting potential equipment failure modes, possible causes, risk levels, and current status, providing data support for maintenance decisions.

- Remaining Useful Life Prediction: Predicts the remaining useful life of equipment, facilitating the shift from "time-based maintenance" to "predictive maintenance."

3.3 Autonomous Recovery and Handling Recommendations

- Function Description: When the system detects an anomaly or fault, it not only issues an alarm but also automatically recommends standardized handling procedures based on its knowledge base and case library.

- Application Example: For instance, upon identifying an "overheated cable termination," the system immediately pushes handling suggestions, including specific steps like "check fastener torque," "clean contact surfaces," and "re-measure with an infrared thermal imager." This guides on-site maintenance personnel to resolve issues quickly and standardly, reducing reliance on expert experience.

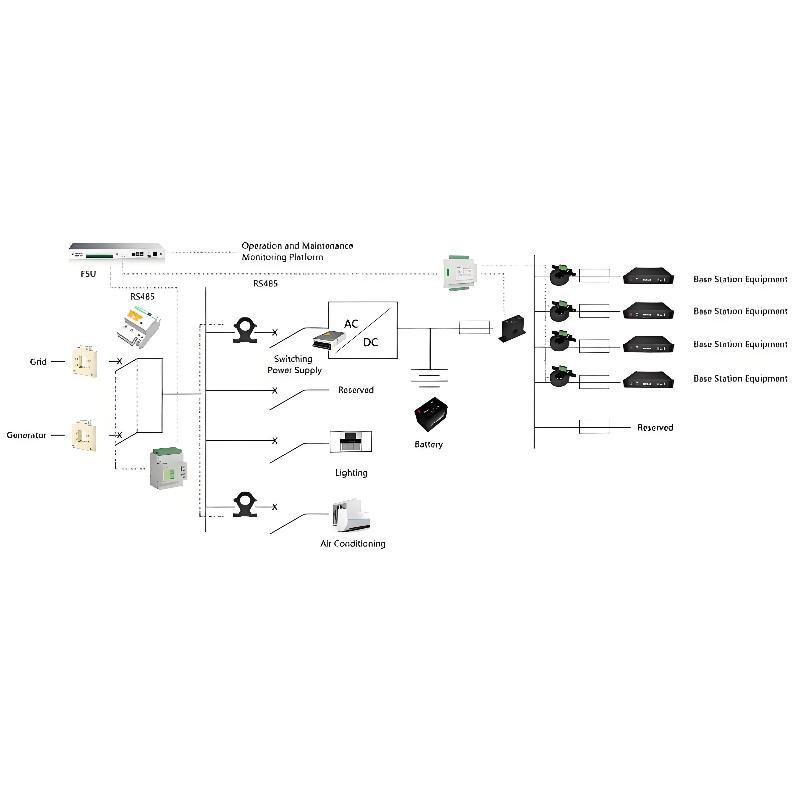

4. Application Scenarios

4.1 Ultra-High Voltage Substations

- Needs: Extremely high requirements for system reliability, as any fault may cause large-scale grid incidents. Equipment is highly valuable, and unplanned outages result in massive losses.

- Value: The precise fault location and equipment health predictive maintenance provided by this system can effectively prevent severe accidents and extend the lifespan of core equipment, serving as a key technical means for ensuring the security of the grid's backbone network.

4.2 Semiconductor Cleanrooms

- Needs: Nearly stringent requirements for power quality (e.g., voltage sags, harmonics) and power supply continuity. Momentary power fluctuations can lead to the scrapping of entire batches of chip products, causing huge economic losses.

- Value: The system can provide early warnings for potential sources of disturbance within the power distribution system (e.g., equipment insulation degradation), preventing their impact on sensitive production equipment. Rapid fault location and handling recommendations can minimize outage duration, ensuring the continuity and stability of the production process.

5. Summary of Core Advantages

- Proactive Warning: Transforms "post-incident remediation" into "preventive action," addressing risks before they materialize.

- Precise Localization: Quickly locates fault points, shortening troubleshooting and recovery time.

- Intelligent Decision-Making: Provides scientific operation and maintenance suggestions based on data-driven insights, enhancing maintenance efficiency.

- Continuous Evolution: Cloud-based AI models update online, making the system smarter with use.

- Secure and Reliable: The "Cloud-Edge" collaborative architecture ensures the real-time performance and reliability of critical operations.