Integrated Smart Power Monitoring and Energy Efficiency Management Solution

- Overview

This solution aims to provide a smart power monitoring system (Power Management System, PMS) centered on end-to-end optimization of power resources. By establishing a closed-loop management framework of "monitoring-analysis-decision-execution," it helps enterprises transition from simply "using electricity" to intelligently "managing electricity," ultimately achieving safe, efficient, low-carbon, and economical energy usage goals.

- Core Positioning

The core positioning of this system is to serve as an enterprise-level power energy "brain."

It is not just a monitoring dashboard but an integrated optimization platform featuring real-time perception, in-depth analysis, intelligent decision-making, and automated control. Its core value lies in bridging data flow and business operations, forming a management closed loop that transforms power data into actionable optimization strategies, directly supporting corporate cost reduction, efficiency improvement, and carbon management.

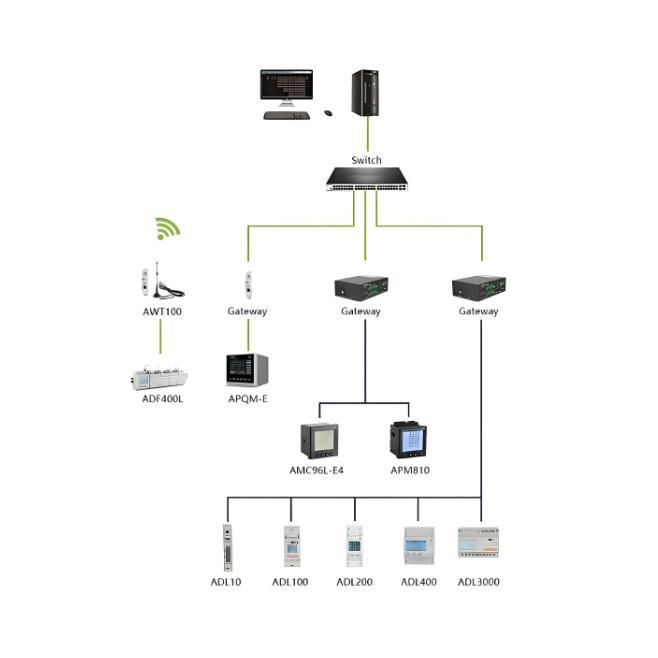

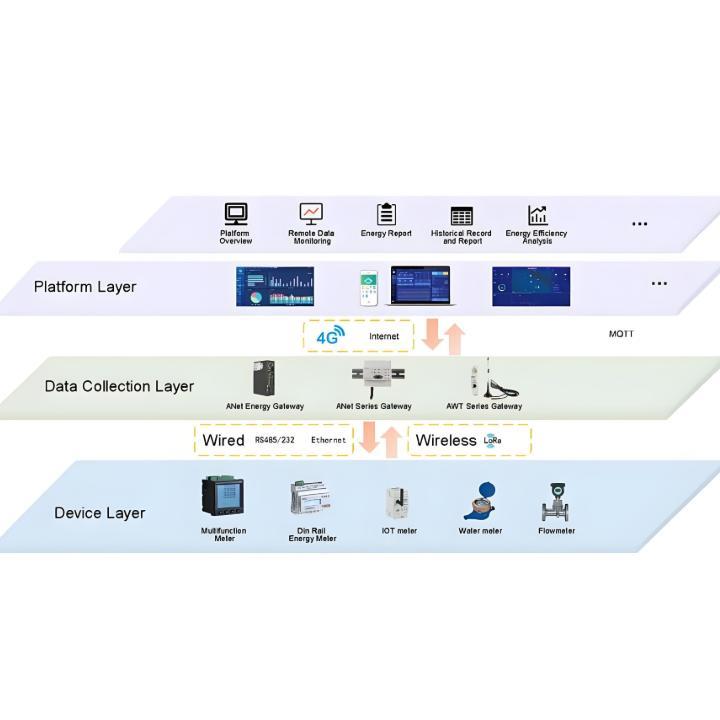

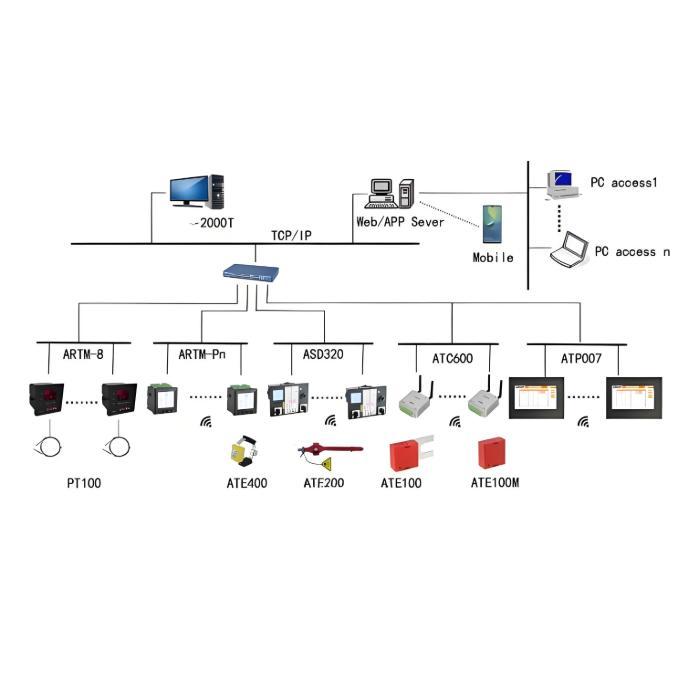

- Technical Architecture: Layered Distributed Architecture

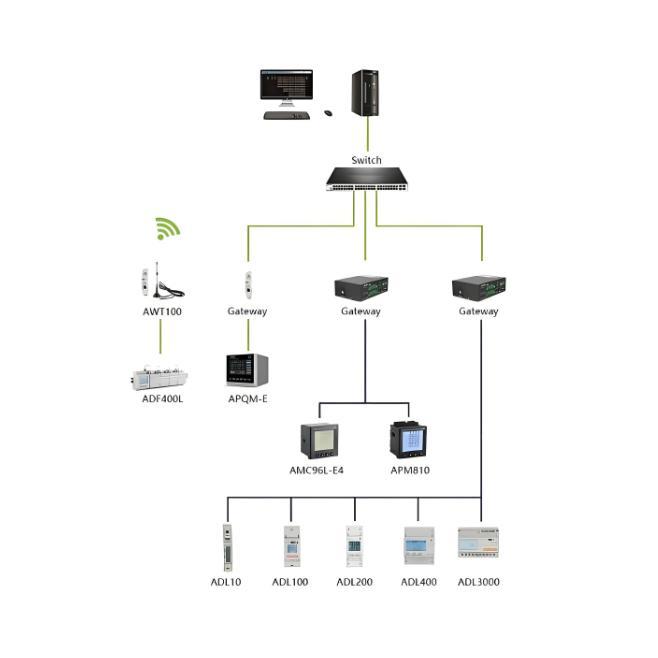

The system adopts an advanced layered distributed technical architecture to ensure reliability, scalability, and ease of maintenance.

- Perception and Execution Layer (Device Layer):

- Integrates various smart meters, power sensors, temperature sensors, IoT gateways, etc., to comprehensively collect key data such as voltage, current, power, power factor, and power quality.

- Deploys edge computing nodes for localized data preprocessing, protocol conversion, and logic control, reducing cloud workload and improving real-time responsiveness.

- Network Communication Layer:

- Employs a hybrid networking approach combining wired (industrial Ethernet) and wireless (4G/5G, LoRa, WiFi) technologies to ensure stable and secure data transmission between the perception layer devices and the platform layer.

- Platform Layer (Brain and Core):

- Data Hub: Built-in time-series database for storing, managing, and efficiently querying massive power data.

- Analysis Engine: Features a core power flow analysis engine integrated with AI algorithms for advanced functions such as load forecasting, peak-valley adjustment, demand response (DR), and energy efficiency analysis.

- Carbon Emission Factor Database: Includes officially recognized and internationally accredited carbon emission factors to ensure accurate carbon accounting.

- Application Layer:

- Provides interactive interfaces via web and mobile apps, presenting data value intuitively to users in management, operations, and maintenance through visual dashboards, reports, and other forms.

- Typical Functional Modules

4.1 Panoramic Monitoring and Safety Warning

- Real-time monitoring of power usage data across entire plants, workshops, production lines, and key equipment.

- Real-time diagnosis and early warning of potential safety hazards such as transformer temperature anomalies, overheated cable connections, and electrical islanding.

- Power quality monitoring (e.g., harmonics, voltage sags/swells) to ensure stable operation of sensitive equipment.

4.2 Intelligent Analysis and Optimization (Core Value Module)

- Dynamic Load Allocation: The system integrates real-time electricity price signals and uses algorithms to generate optimal production scheduling suggestions or directly control adjustable loads (e.g., air conditioners, air compressors, charging piles). It automatically shifts high-energy-consumption equipment operation to off-peak hours, significantly reducing electricity costs.

- Energy Efficiency Benchmarking Analysis: Establishes enterprise-specific energy efficiency baselines (KPIs) and compares them with industry benchmarks to identify energy consumption anomalies and energy-saving opportunities, generating diagnostic reports.

- Load Forecasting and Demand Response: Accurately predicts short-term load based on historical data and factors like weather. Automatically or manually participates in grid demand response events by reducing specific loads to generate revenue.

4.3 Carbon Emission Management Module

- Automated Carbon Accounting: Integrates a carbon emission factor database to automatically generate carbon footprint reports for enterprises or products based on collected data of electricity, gas, water, coal, and other energy consumption, meeting compliance disclosure requirements.

- Carbon Emission Trend Analysis: Visualizes trends in total carbon emissions and emission intensity, providing data support for developing carbon reduction pathways.

4.4 Comprehensive Reporting and Management

- Automatically generates daily, weekly, monthly, and annual reports on electricity usage, billing, energy savings, and carbon emissions, supporting one-click export to significantly reduce manual workload.

- Application Scenarios

- Energy-Intensive Manufacturing (e.g., steel, chemicals, metallurgy, automotive):

- Precisely monitors large energy-consuming equipment such as furnaces, rolling mills, and air compressor stations, achieving significant energy savings through process optimization and load adjustment.

- Electricity costs are a major expense, making peak-valley adjustment highly cost-effective.

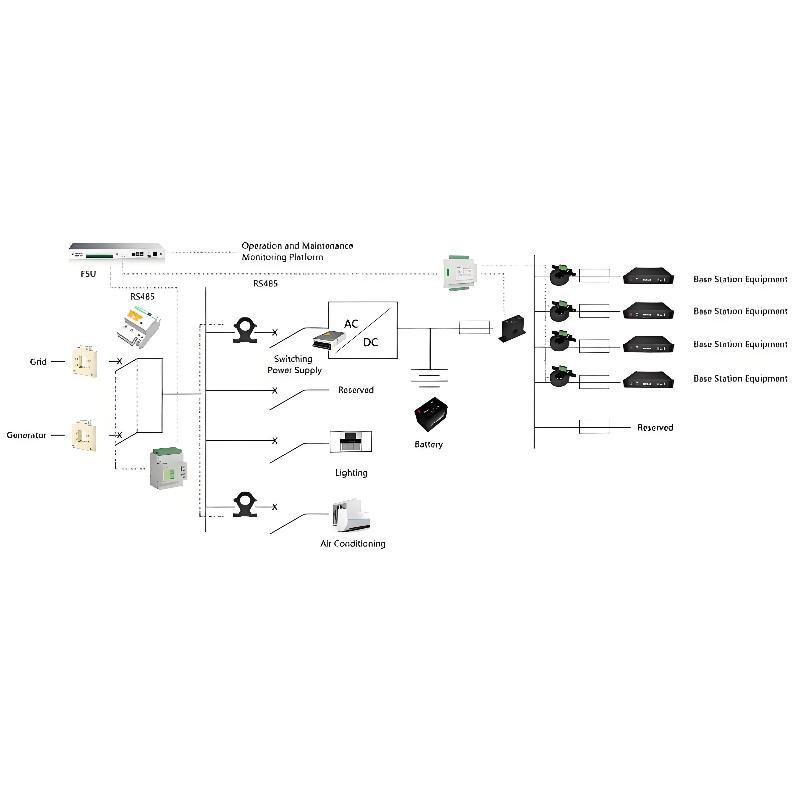

- Data Centers:

- Monitors power usage efficiency (PUE) of key facilities such as IT equipment, cooling systems (precision air conditioning), and UPS.

- Continuously optimizes PUE by dynamically adjusting cooling strategies and IT loads, reducing operational costs.

- Commercial Complexes/Large Public Buildings:

- Implements sub-metering and intelligent control of HVAC, lighting, elevators, parking systems, etc.

- Enables on-demand supply of air conditioning and lighting based on passenger flow and environmental parameters, improving energy efficiency and comfort.

- Core Advantages

- Closed-Loop Intelligence: Focuses not only on "monitoring" but also on "analysis" and "control," forming a management closed loop to fully unleash data value.

- Precise Cost Reduction: Directly reduces electricity costs through load forecasting and peak-valley adjustment.

- Proactive Safety: Identifies electrical hazards in advance, shifting from "reactive maintenance" to "proactive warning" to ensure production safety.

- Low-Carbon Compliance: Provides a one-stop solution for carbon accounting and management, supporting green and sustainable development.

- High Scalability: The layered distributed architecture allows flexible expansion of monitoring points and functional modules based on business needs.