Rockwill Automatic Recloser: Empowering the Automation of Tanzania's Distribution Network and Illuminating a New Future for Africa's Energy Sector

In the process of energy development on the African continent, Tanzania's power sector is undergoing a crucial upgrading transformation. As an important pillar for Tanzania's economic and social development, the stable operation and automation level of the distribution network are directly related to the daily life of the people, the continuous advancement of industrial production, and the growth vitality of the regional economy. However, for a long time, the distribution network in some regions of Tanzania has been plagued by problems such as frequent line faults, low efficiency in fault detection, and long power outage durations. Especially in densely populated and economically active areas like Dar es Salaam-Lindi-Mtwara and Mwanza-Bukoba, the traditional distribution operation and maintenance model can no longer meet the growing electricity demand, making the automation upgrade of the distribution network an urgent priority.

Just as the Tanzania Electric Supply Company (TANESCO) was seeking a breakthrough to address these distribution network challenges, the introduction of Rockwill Automatic Recloser brought it a brand-new solution, successfully helping Tanzania's distribution network enter a new era of automation.

Rockwill’s Feeder Automation Terminal Unit(FTU) is equipped with comprehensive and powerful protection functions, building a solid "safety barrier" for Tanzania's distribution lines. This terminal not only has the core automatic recloser function—capable of quickly restoring power supply when a transient fault occurs in the distribution line and reducing the impact of power outages on users—but also integrates multiple protection functions, including three-stage current/ground current protection, low-current ground protection, curve protection, overload protection, overvoltage/undervoltage protection, and frequency protection. Whether facing line overload, abnormal voltage fluctuations, ground faults, or other power-related issues, the terminal can accurately monitor and respond in a timely manner, effectively preventing the expansion of faults, ensuring the stable operation of distribution lines, and providing strong support for the safety and reliability of Tanzania's power system.

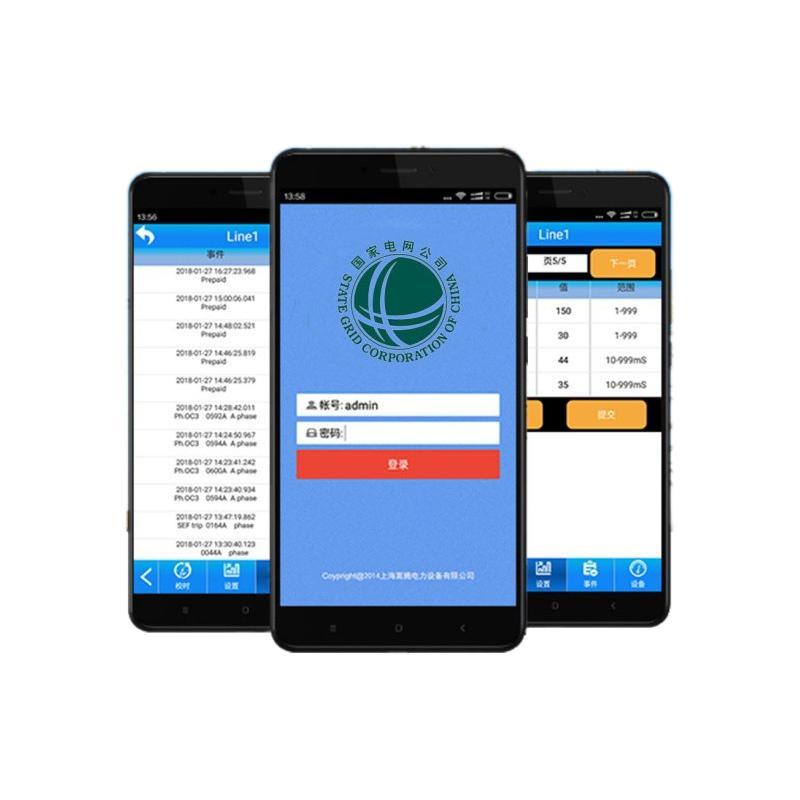

In terms of communication and automation integration, Rockwill’s FTU demonstrates excellent compatibility and efficiency, perfectly adapting to the Automation Management needs of TANESCO. The terminal is equipped with multiple communication interfaces and fully supports a variety of mainstream communication protocols such as IEC60870-101/104, DNP3.0, Modbus, and IEC61850. It can be easily connected to the power company's SCADA system (Supervisory Control And Data Acquisition), truly realizing the "remote signaling, remote measurement, remote control, and remote regulation" functions of the distribution network. Through the SCADA system, operation and maintenance personnel can remotely obtain real-time operating data of distribution lines (such as key parameters like current, voltage, and power), promptly grasp information such as line switch status and fault alarms, and even remotely control terminal equipment and adjust operating parameters. This breakthrough has completely changed Tanzania's traditional manual inspection and on-site operation model, making distribution network management more intelligent and efficient.

In this cooperation, Rockwill shipped a total of 132 automatic recloser devices to TANESCO. Based on the distribution needs of different regions, these devices were scientifically allocated to core areas including Dar es Salaam-Lindi-Mtwara, Njombe-Mbeya, Iringa-Dodoma-Singida, Mwanza-Bukoba, and Babati-Arusha. After being installed on the distribution lines, these devices quickly took effect and delivered an impressive "performance report":

- A total of 151 successful reclosing were achieved, meaning 151 transient faults were resolved promptly, saving countless households and enterprises from unnecessary power outages;

- 13 faults were successfully isolated, with fault sections accurately located and segregated to prevent the spread of faults to a larger area, minimizing the impact of faults to the greatest extent.

- More importantly, through efficient fault handling and automated management, the total power outage duration was reduced by 240 hours, significantly improving the reliability of power supply and providing stable support for the daily life of Tanzanian people and the continuous operation of industrial production.

- At the same time, the inspection time was shortened by 50 hours, greatly reducing the work intensity of operation and maintenance personnel, improving operational efficiency, and saving TANESCO a great deal of human and time costs.

From solving the actual pain points of Tanzania's distribution network to driving a leapfrog improvement in its automation level, Rockwill Automatic Recloser has proven its value with tangible results. In the future, Rockwill will continue to uphold the concept of technological innovation, deepen its presence in the field of power automation, and provide high-quality solutions for the development of the power industry in more countries and regions. It will contribute to advancing the global energy system toward a more intelligent, reliable, and efficient future, and jointly illuminate a new path for sustainable energy development.

Application training for the ARC equipment