| Brand | Rw Energy |

| Model NO. | Active Power Filter (APF) |

| Rated voltage | 400V |

| Series | APF |

Product Overview

Active Power Filter (APF) is a high-performance power quality optimization device designed specifically for medium and low voltage distribution networks. Its core functions focus on harmonic control and precise reactive power compensation, which can quickly capture and suppress harmonic interference in the power grid, while also taking into account reactive power regulation, effectively improving power quality, reducing line losses, and ensuring safe and stable operation of electrical equipment. As a fully controlled power electronic device, APF adopts advanced detection algorithms and power conversion technology, with fast response speed and high compensation accuracy. It can achieve wideband harmonic suppression without the need for additional filtering components and is suitable for various scenarios with nonlinear loads. It is a core equipment for solving harmonic pollution and improving power grid reliability.

System structure and working principle

Core structure

Detection unit: Integrated high-precision current/voltage detection module, real-time collection of current signals from the power grid and load, precise separation of harmonic components and reactive current through FFT and fast Fourier transform technology, providing data support for compensation control.

Control unit: Equipped with a dual core control system of DSP and FPGA, it has fast computing speed and precise control logic. It is linked with the main circuit module through a high-speed communication bus (RS-485/CAN/Ethernet) to achieve real-time command issuance and status monitoring.

Main circuit module: The bridge inverter circuit is composed of high-performance IGBT power modules, which have strong overload capacity and stable operation characteristics, and can quickly generate compensation current according to control instructions; Equipped with filtering and protection units to achieve current limiting, overvoltage protection, and electromagnetic compatibility.

Auxiliary structure: including dual power supply modules, cooling systems, and protective cabinets to ensure continuous and stable operation of the equipment under complex working conditions.

Working principle

The controller monitors the nonlinear load current in the power grid in real time through the detection unit, uses FFT fast Fourier transform technology to analyze the amplitude and phase information of each harmonic current, and instantly calculates the required reverse compensation current parameters. Subsequently, the switching state of the IGBT module is controlled through PWM pulse width modulation technology to generate compensation current with equal amplitude and opposite phase to the harmonic current, which is accurately injected into the power grid and cancels out the harmonic current generated by the load. At the same time, reactive power can be dynamically adjusted according to demand, ultimately achieving sinusoidal current and power factor optimization in the power grid, significantly reducing harmonic distortion rate (THDi), and ensuring that power quality meets relevant national standards.

Cooling method

Forced cooling (AF/Air Cooling)

Water Cooling

Main Features

Accurate and efficient harmonic suppression: It can suppress 2-50 harmonics, reduce the harmonic distortion rate THDi to below 5%, and achieve a compensation current resolution of 0.1A. It can accurately respond to complex harmonics generated by nonlinear loads such as frequency converters, arc furnaces, rectifiers, etc.

Rapid response and dynamic compensation: With a response time of less than 5ms, it can track the dynamic changes of load harmonics and reactive power in real time without delay compensation, effectively solving the problem of power quality fluctuations caused by impact loads.

Stable and reliable, with strong adaptability: adopting a dual power supply design and redundant protection mechanism, it has multiple protection functions such as overvoltage, undervoltage, overcurrent, overheating, and drive failure; The protection level reaches IP30 (indoor)/IP44 (outdoor), can withstand operating temperatures of -35 ℃~+40 ℃, and is suitable for various harsh working conditions.

Flexible functionality, compatible with expansion: supports separate compensation for harmonics, separate compensation for reactive power, or a combination of both compensation modes; Compatible with multiple communication protocols such as Modbus RTU and IEC61850, it can achieve parallel network operation of multiple machines and meet the requirements of different capacity scenarios.

Energy saving and environmentally friendly, economical and practical: its own power loss is less than 1%, no additional harmonic generation, and does not affect the original structure of the power grid; No need for large capacity capacitors or inductive components, compact structure, saving installation space and initial investment.

Technical Specifications

Name |

specifications |

|

APF |

3-Phase,3-wire |

3-Phase,4-wire |

Rated compensation current |

100A-600A |

50A-600A |

Working voltage |

400V(-20% ~ +15%) 690V(-20% ~ +15%) |

400V(-20% ~ +15%) |

Working frequency(Hz) |

50/60 |

50/60 |

Harmonic compensation range |

2-50 harmonics |

|

Response time |

<10ms |

|

THDI |

<3%(Rated) |

|

Overload |

≤100% |

|

Display |

LCD |

|

Display value |

Current and Voltage |

|

Communication |

Modbus,RS485,TCP/IP,ETH |

|

Working temperature |

-10℃~45℃ |

|

Humidity |

≤90% |

|

Installation site |

Indoor |

|

Altitude |

≤1000m |

|

Application scenarios

Industrial sectors: Steel, metallurgy (electric arc furnaces, continuous casting machines), mining (frequency converter driven equipment), petrochemicals (compressors, pumps), automotive manufacturing (welding equipment, coating lines) and other scenarios with a large number of nonlinear loads, to control harmonic pollution and ensure stable operation of production equipment.

Commercial and civil buildings: central air conditioning, elevators, lighting systems for office buildings, shopping malls, hotels, UPS power supplies for data centers, server clusters, to suppress harmonic interference and avoid damage to electrical equipment.

In the field of new energy, the inverter side of photovoltaic power plants and wind farms is used to control the harmonics generated by inverters, improve the quality of new energy grid connected electricity, and meet grid access standards.

In the field of transportation: electrified railway traction stations, urban rail transit power supply systems, solve the harmonic and negative sequence problems generated by traction loads, and stabilize the power supply voltage.

Other scenarios: medical equipment, precision instrument production lines, airport and port lifting equipment, and other scenarios that require strict power quality, providing a pure power environment.

Capacity selection core: harmonic current calculation+scene correction, specific methods are as follows:

- Basic accounting: The total harmonic current (Ih) of the load is measured by a power quality analyzer, and the rated current of the APF should be ≥ 1.2~1.5 times Ih (with redundancy reserved);

- Power conversion: When the percentage of harmonic content (THD_i) and the active power of the load (P) are known, they can be estimated using the formula Ipf=P × THD_i/(√ 3 × U_n × cos φ) (U_n is the rated voltage, cos φ is the load power factor);

- Scene correction: Impact loads (such as electric arc furnaces and welding equipment) x 1.5~2.0, steady-state loads (such as air conditioning and lighting) x 1.2~1.3; High altitude/high temperature environment × 1.1-1.2;

- Expansion suggestion: Modular models should reserve 10% to 20% expansion space to avoid insufficient compensation due to increased load.

Both are power quality optimization devices, but their functional focus and application scenarios are different:

APF (Active Power Filter): The core function is harmonic control, which can accurately suppress 2-50 harmonics and also has a small amount of reactive power compensation capability. It is suitable for scenarios with severe harmonic pollution (such as frequency converters and rectifier loads), and prioritizes solving the problem of THDi exceeding the standard.

SVG (Static Var Generator): The core function is reactive power compensation, achieving power factor optimization and voltage stability, with harmonic suppression as an auxiliary function. It is suitable for scenarios with large reactive power fluctuations (such as new energy and impact loads), and prioritizes solving low power factor and voltage flicker problems.

Selection core: APF is mainly selected for harmonic exceedance, and SVG is mainly selected for reactive power deficiency and voltage fluctuation. The two can be used together to achieve comprehensive governance of "harmonic+reactive power".

-

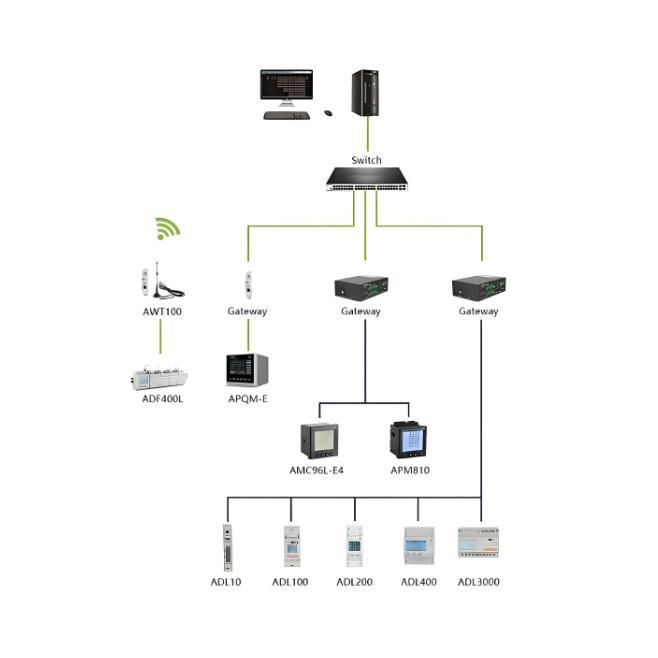

Integrated Smart Power Monitoring and Energy Efficiency Management SolutionOverviewThis solution aims to provide a smart power monitoring system (Power Management System, PMS) centered on end-to-end optimization of power resources. By establishing a closed-loop management framework of "monitoring-analysis-decision-execution," it helps enterprises transition from simply "using electricity" to intelligently "managing electricity," ultimately achieving safe, efficient, low-carbon, and economical energy usage goals. Core PositioningThe core positioning of this system is tRW Energy28/09-2025

Integrated Smart Power Monitoring and Energy Efficiency Management SolutionOverviewThis solution aims to provide a smart power monitoring system (Power Management System, PMS) centered on end-to-end optimization of power resources. By establishing a closed-loop management framework of "monitoring-analysis-decision-execution," it helps enterprises transition from simply "using electricity" to intelligently "managing electricity," ultimately achieving safe, efficient, low-carbon, and economical energy usage goals. Core PositioningThe core positioning of this system is tRW Energy28/09-2025 -

A Novel Modular Monitoring Solution for Photovoltaic and Energy Storage Power Generation Systems1.Introduction and Research Background1.1 Current State of the Solar IndustryAs one of the most abundant renewable energy sources, the development and utilization of solar energy has become central to the global energy transition. In recent years, driven by policies worldwide, the photovoltaic (PV) industry has experienced explosive growth. Statistics indicate that China's PV industry saw a staggering 168-fold increase during the "12th Five-Year Plan" period. By the end of 2015, the installedRW Energy28/09-2025

A Novel Modular Monitoring Solution for Photovoltaic and Energy Storage Power Generation Systems1.Introduction and Research Background1.1 Current State of the Solar IndustryAs one of the most abundant renewable energy sources, the development and utilization of solar energy has become central to the global energy transition. In recent years, driven by policies worldwide, the photovoltaic (PV) industry has experienced explosive growth. Statistics indicate that China's PV industry saw a staggering 168-fold increase during the "12th Five-Year Plan" period. By the end of 2015, the installedRW Energy28/09-2025 -

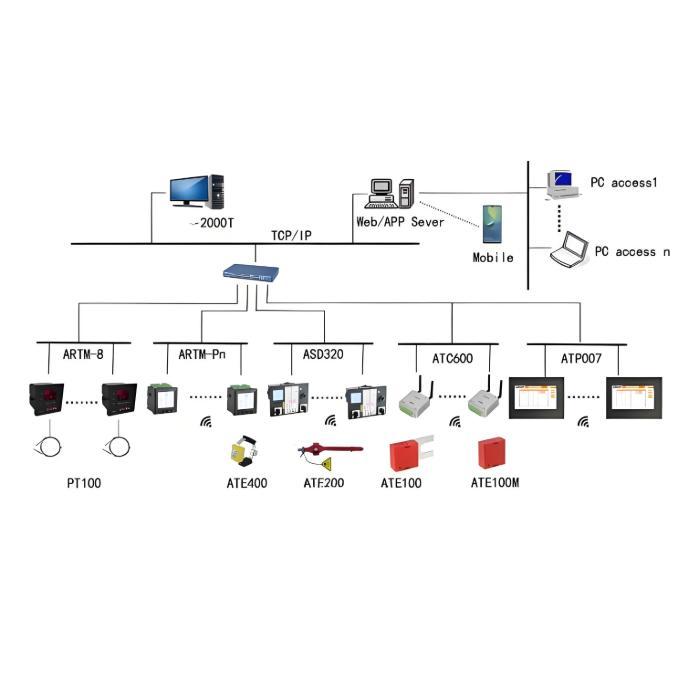

Comprehensive Power Quality Diagnostic Expert System Solution1.Core PositioningThis solution is designed to provide a comprehensive, multi-dimensional power quality diagnostic expert system. It moves beyond traditional data acquisition and monitoring, deeply integrating advanced analysis and diagnostic functions, positioning itself as an enterprise's "Comprehensive Physician for Power Quality." It can accurately capture, deeply analyze, and intelligently diagnose various types of power quality issues within the electrical grid. It offers users a full-chaRW Energy28/09-2025

Comprehensive Power Quality Diagnostic Expert System Solution1.Core PositioningThis solution is designed to provide a comprehensive, multi-dimensional power quality diagnostic expert system. It moves beyond traditional data acquisition and monitoring, deeply integrating advanced analysis and diagnostic functions, positioning itself as an enterprise's "Comprehensive Physician for Power Quality." It can accurately capture, deeply analyze, and intelligently diagnose various types of power quality issues within the electrical grid. It offers users a full-chaRW Energy28/09-2025 -

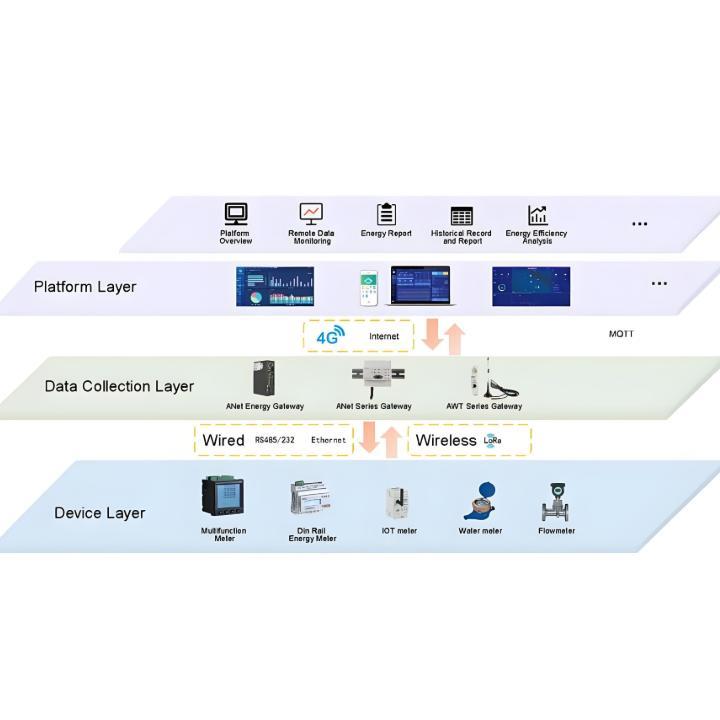

Ubiquitous Energy Management System Solution for Smart Cities and Integrated Parks1.Overview and Core PositioningThe core positioning of this system is: a comprehensive platform for the collaborative management and optimization of multiple energy flows, including water, electricity, gas, and heat. It goes beyond traditional power monitoring by breaking down energy data silos. Through integration, analysis, optimization, and prediction, it serves as an "energy brain" that provides panoramic visibility, intelligent decision-making, and deep value for various energy consumers sRW Energy28/09-2025

Ubiquitous Energy Management System Solution for Smart Cities and Integrated Parks1.Overview and Core PositioningThe core positioning of this system is: a comprehensive platform for the collaborative management and optimization of multiple energy flows, including water, electricity, gas, and heat. It goes beyond traditional power monitoring by breaking down energy data silos. Through integration, analysis, optimization, and prediction, it serves as an "energy brain" that provides panoramic visibility, intelligent decision-making, and deep value for various energy consumers sRW Energy28/09-2025 -

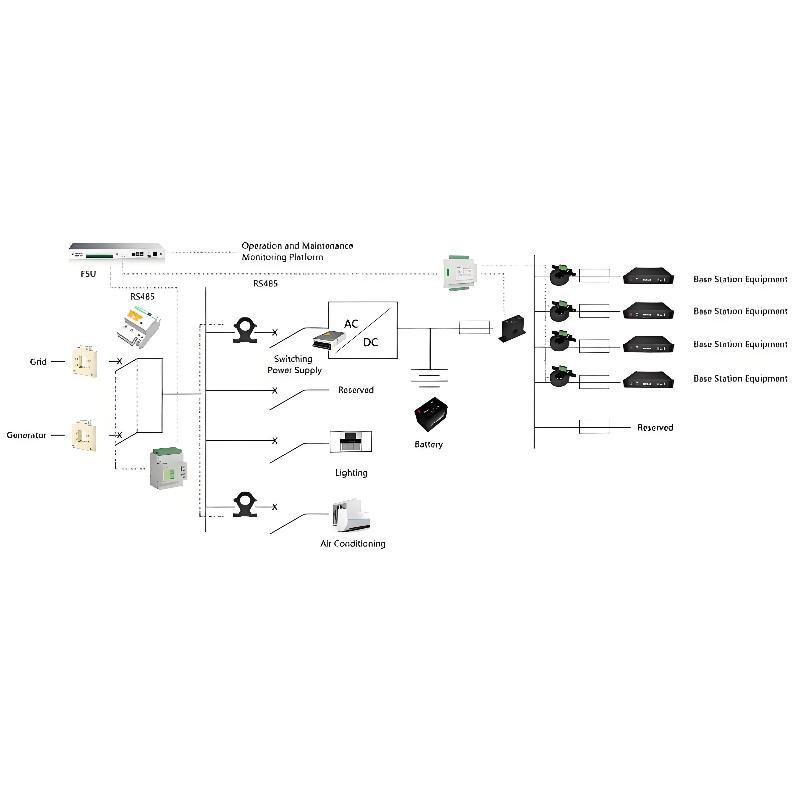

Intelligent Power Monitoring: Smart Power Monitoring System Solution1.System OverviewCore Positioning: AI-Driven Adaptive Power Security GuardianThe Intelligent Power Monitoring system is a new-generation power monitoring solution designed for the future. It breaks through the limitations of "passive alarm" inherent in traditional monitoring systems. By integrating edge computing, cloud computing, and artificial intelligence technologies, it constructs an integrated active defense system encompassing "perception - analysis - decision - early warning." The coRW Energy28/09-2025

Intelligent Power Monitoring: Smart Power Monitoring System Solution1.System OverviewCore Positioning: AI-Driven Adaptive Power Security GuardianThe Intelligent Power Monitoring system is a new-generation power monitoring solution designed for the future. It breaks through the limitations of "passive alarm" inherent in traditional monitoring systems. By integrating edge computing, cloud computing, and artificial intelligence technologies, it constructs an integrated active defense system encompassing "perception - analysis - decision - early warning." The coRW Energy28/09-2025 -

High-Precision Electrical Parameter Monitoring System Solution1.IntroductionWith the increasingly stringent requirements for power supply quality in high-end facilities such as precision manufacturing, medical diagnosis, and data centers, traditional power monitoring systems, due to their low sampling accuracy and weak data analysis capabilities, can no longer meet the demand for deep insight and precise management of power quality. In response, we are introducing a new generation High-Precision Electrical Parameter Monitoring System. With millisecond-lRW Energy28/09-2025

High-Precision Electrical Parameter Monitoring System Solution1.IntroductionWith the increasingly stringent requirements for power supply quality in high-end facilities such as precision manufacturing, medical diagnosis, and data centers, traditional power monitoring systems, due to their low sampling accuracy and weak data analysis capabilities, can no longer meet the demand for deep insight and precise management of power quality. In response, we are introducing a new generation High-Precision Electrical Parameter Monitoring System. With millisecond-lRW Energy28/09-2025