Motion Controller

| Brand | Rw Energy |

| Model NO. | Motion Controller |

| Rated voltage | 24V |

| Series code | 200 |

| Product edition code | Economic Edition |

| Series | MC |

MC motion controller is designed for complex single-device motion control applications, such as CNC machines, industrial robots, semiconductors, and engineering machinery. MC delivers high-speed, high-precision multi-axis control, supporting up to 64 axes in one system. It also features extensive, user-friendly algorithm libraries for versatile performance.

features:

High Compatibility

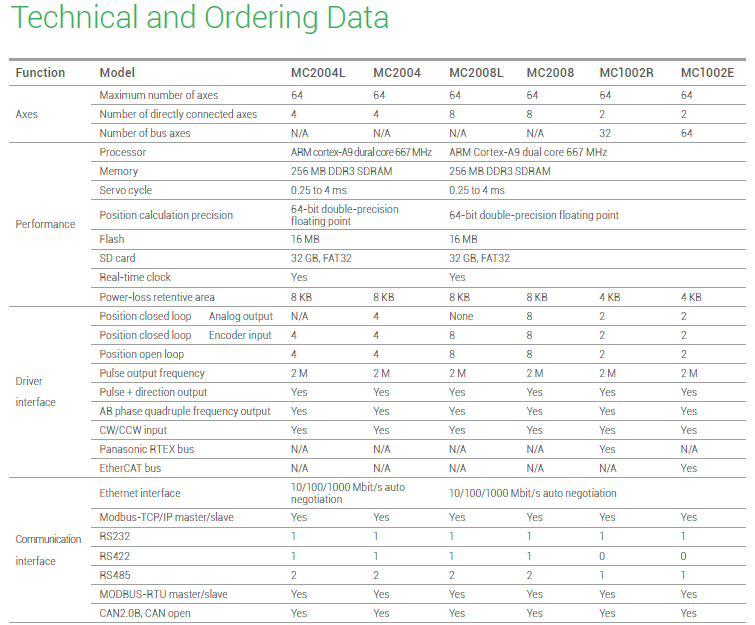

Supporting EtherCAT MC1002E and RTEX MC1002R

Compatible with servo drivers from multiple manufacturers

Seamless integration with LE

High Performance

250 μs servo control cycle

Up to 64-axis control per system

64-level look-ahead buffer

Multiple Control Modes

Open/closed-loop pulse servo control

Open/closed-loop analog servo control

Open/closed-loop bus servo control

Ordinary PLCs focus on logic control, while this product is specifically designed for "high-speed+high-precision" motion scenarios: microsecond level response, built-in kinematic algorithm library, and anti vibration interference design. In production lines that require both rhythm and accuracy, such as lithium battery winding and photovoltaic cutting, the scrap rate can be reduced by more than 15%, making it a core tool for improving quality and efficiency in high-end manufacturing.

Fully compatible with mainstream servo drives such as Yaskawa, Panasonic, and Huichuan at home and abroad, supporting EtherCAT/RTEX dual bus protocol. Paired with RW Energy intelligent debugging software, it provides graphical axis parameter configuration and one click self-tuning function. Engineers can complete multi axis joint debugging in 30 minutes, greatly shortening project delivery cycles and reducing technical dependence.

Supports up to 64 axis synchronous control, equipped with 250 μ s servo control cycle and 64 level forward-looking buffer technology, accurately realizing complex processes such as electronic cam, flying shear, trajectory interpolation, etc. It has been successfully applied in industrial robot trajectory tracking, semiconductor wafer handling, high-end CNC machine tools and other scenarios, with a positioning accuracy of ± 0.01mm, helping customers improve production line efficiency by more than 30%.